Imininingwane

Uchungechunge lwe-SILIKE Si-TPV 3100 luyi-elastomer eguquguqukayo esekelwe ku-thermoplastic thermoplastic, eyakhiwe ngobuchwepheshe obukhethekile obuhambisanayo obuqinisekisa ukuthi irabha ye-silicone ihlakazeka ngokulinganayo ku-TPU njengezinhlayiya ze-micron ezingu-2-3 ngaphansi kwe-microscope. Le nhlanganisela eyingqayizivele inikeza amandla, ukuqina, kanye nokumelana nokuguguleka okuvamile kwama-elastomer e-thermoplastic ngenkathi ifaka izakhiwo ezifiselekayo ze-silicone, njengokuthamba, umuzwa othambile, kanye nokumelana nokukhanya kwe-UV namakhemikhali. Okubalulekile, lezi zinto zingasetshenziswa kabusha futhi zingasetshenziswa kabusha ezinqubweni zokukhiqiza zendabuko.

Uchungechunge lwe-Si-TPV 3100 lwenzelwe ngqo izinhlelo zokusebenza zokubumba ezithambile, ezibonisa ukuguguleka okuhle kakhulu kanye nokumelana namakhemikhali. Lungaxhunyaniswa nezinhlobo ezahlukene zepulasitiki zobunjiniyela be-thermoplastic, kufaka phakathi i-PC, i-ABS, ne-PVC, ngaphandle kwezinkinga ezifana nokuna kwemvula noma ukunamathela ngemva kokuguga.

Ngaphezu kokusebenza njengezinto zokusetshenziswa, i-Si-TPV 3100 Series isebenza njengesithasiselo sokulungisa i-polymer kanye ne-processing ye-thermoplastic elastomers kanye namanye ama-polymer. Ithuthukisa ukuqina, ithuthukisa izici zokucubungula, futhi ithuthukisa izakhiwo zomphezulu. Uma ixutshwe ne-TPE noma i-TPU, i-Si-TPV inikeza ubushelelezi bomphezulu obuhlala njalo kanye nomuzwa omuhle wokuthinta, ngenkathi ithuthukisa nokumelana nokuklwebheka nokuklwebheka. Inciphisa ngempumelelo ubulukhuni ngaphandle kokubeka engcupheni izakhiwo zomshini, futhi ithuthukisa ukuguga, ukuphuzi, kanye nokumelana namabala, okuvumela ukuqeda okufiselekayo kwe-matte.

Ngokungafani nezithasiselo ze-silicone ezivamile, i-Si-TPV inikezwa ngesimo se-pellet, okwenza kube lula ukuyicubungula njenge-thermoplastic. Ihlakazeka kahle nangokulinganayo kuyo yonke i-polymer matrix, lapho i-copolymer ihlangana khona ngokomzimba ne-matrix. Lesi sici sisusa ukukhathazeka mayelana nokufuduka noma "ukuqhakaza," sibeka i-Si-TPV njengesixazululo esisebenzayo nesisha sokufeza izindawo ezithambile ezithambile ngokuzwakala okomile ku-TPU nakwamanye ama-elastomer e-thermoplastic ngaphandle kokudinga izinyathelo ezengeziwe zokucubungula noma zokugqoka.

Izinzuzo Eziyinhloko

- Ku-TPU

- 1. Ukunciphisa ubulukhuni

- 2. Ama-haptic amahle kakhulu, ukuthinta okomile okusilika, akukho ukuqhakaza ngemuva kokusetshenziswa isikhathi eside

- 3. Nikeza umkhiqizo wokugcina we-TPU indawo enombala ocwebezelayo

- 4. Yandisa isikhathi sokuphila kwemikhiqizo ye-TPU

Ukuqina Ukuqina

- Ubuchwepheshe obuthuthukisiwe obungenazo izinyibilikisi, ngaphandle kwe-plasticizer, akukho uwoyela wokuthambisa, futhi awunaphunga.

- Ukuvikelwa kwemvelo kanye nokusetshenziswa kabusha kwayo.

- Itholakala ngezinhlobo ezihambisana nomthetho.

Izifundo Zezimo Zesithasiselo sepulasitiki se-Si-TPV kanye nesiguquli se-polymer

Uchungechunge lwe-Si-TPV 3100 lubonakala ngokuthinta kwalo okuthambile okuhlala isikhathi eside futhi okunobungani nesikhumba kanye nokumelana okuhle kakhulu namabala. Lungenazo izinto zokupholisa nokupholisa, luqinisekisa ukuphepha nokusebenza ngaphandle kwemvula, ngisho nangemva kokusetshenziswa isikhathi eside. Lolu chungechunge luyisithasiselo sepulasitiki esisebenzayo kanye nesiguquli se-polymer, okwenza lufaneleke kakhulu ekuthuthukiseni i-TPU.

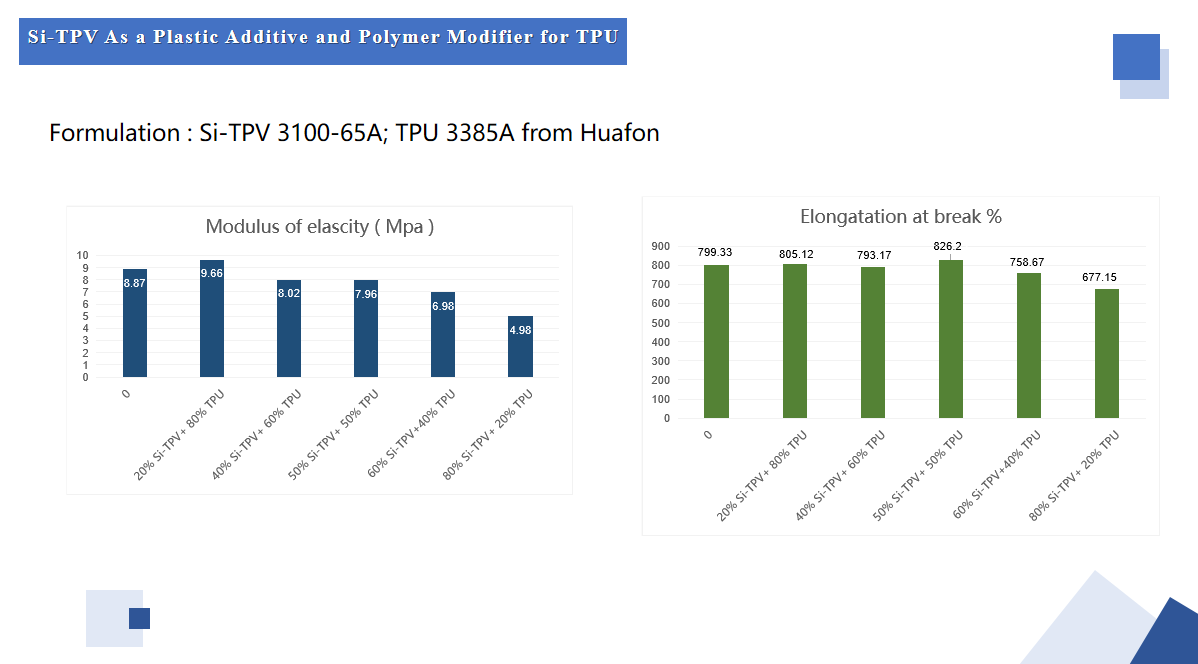

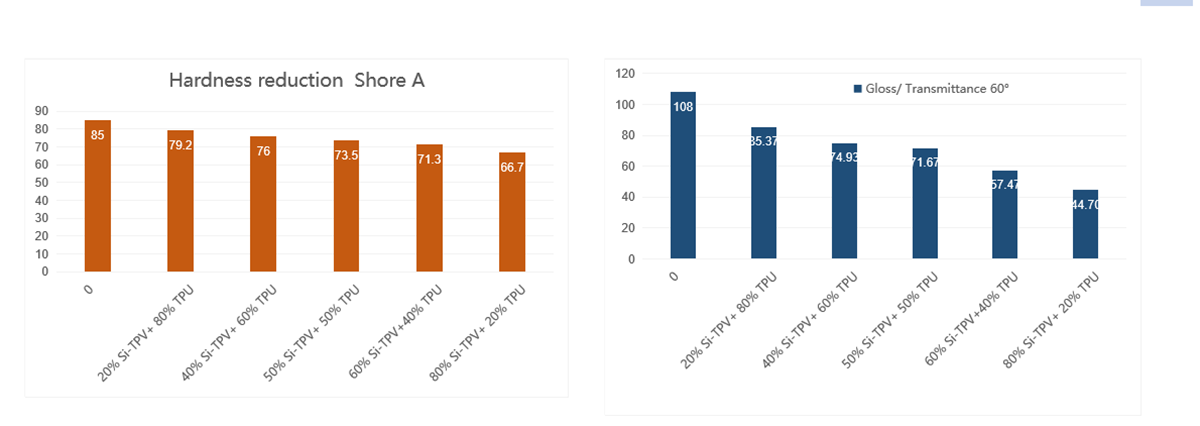

Ngaphezu kokunikeza umuzwa othambile nomnandi, i-Si-TPV inciphisa ngempumelelo ubulukhuni be-TPU, ifinyelele ibhalansi efanele yenduduzo nokusebenza. Iphinde ifake isandla ekuqedeni kobuso obungacwebezeli ngenkathi ihlinzeka ngokuqina nokumelana nokuguguleka, okwenza kube ukukhetha okuhle kwezinhlelo zokusebenza ezahlukahlukene.

Ukuqhathanisa Imiphumela ye-Si-TPV Plastic Additive kanye ne-Polymer Modifier ku-TPUUkusebenza

Isicelo

Ukuguqulwa kobuso be-thermoplastic polyurethane (TPU) kuvumela izici zayo ukuthi zisetshenziswe ngendlela ethile ngenkathi kugcinwa izakhiwo ezinkulu. Ukusebenzisa i-SILIKE's Si-TPV (dynamic vulcanized thermoplastic silicone-based elastomer) njengesithasiselo senqubo esisebenzayo kanye nesiguquli sokuzizwa sama-thermoplastic elastomers kuveza ikhambi eliwusizo.

Ngenxa ye-Si-TPV dynamic vulcanized thermoplastic silicone-based elastomer, inikeza izinzuzo eziningana, okuhlanganisa ukuthinta okuthambile okuhlala isikhathi eside, okunobungani nesikhumba, ukumelana okuhle kwamabala, kanye nokungabikho kwama-plasticizer noma ama-softeners, okuvimbela imvula ngokuhamba kwesikhathi.

Njengesithasiselo sepulasitiki esisekelwe ku-silicone kanye nesiguquli se-polymer, i-Si-TPV inciphisa ubulukhuni futhi ithuthukise ukuguquguquka, ukunwebeka, kanye nokuqina. Ukufakwa kwayo kuveza ubuso obuthambile, obomile obufana nosilika obuhlangabezana nokulindelwe ngabasebenzisi ezintweni eziphathwa njalo noma ezigqokwayo, okwandisa kakhulu izinhlelo zokusebenza ezingaba khona ze-TPU.

I-Si-TPV ihlangana kahle nezindlela ze-TPU, ikhombisa imiphumela emibi embalwa engathandeki uma iqhathaniswa nemikhiqizo ye-silicone evamile. Lokhu kuguquguquka kwamakhemikhali e-TPU kuvula amathuba emikhakheni ehlukahlukene, okuhlanganisa izimpahla zabathengi, izingxenye zezimoto, izintambo zokushaja ze-EV, amadivayisi ezokwelapha, amapayipi amanzi, amapayipi, kanye nemishini yezemidlalo—lapho induduzo, ukuqina, kanye nokukhanga kobuhle kubalulekile khona.

Izixazululo:

Lokho Abakhiqizi Okudingeka Bakwazi Ngobuchwepheshe Be-TPU Obuguquliwe kanye Nezixazululo Zezinto Ezintsha Zamakhebula Namapayipi Okushaja Amapayipi E-EV!

1. Ubuchwepheshe be-TPU (thermoplastic polyurethane) obuguquliwe

Ukuguqulwa kwezindawo ze-TPU kubalulekile ekwakheni izinto ezingakhulisa ukusebenza kahle kwezicelo ezithile. Okokuqala, sidinga ukuqonda Ubulukhuni be-TPU kanye Nokuqina. Ubulukhuni be-TPU bubhekisela ekumelaneni kwezinto ezifakwe ngaphakathi noma ekuguqukeni ngaphansi kwengcindezi. Amanani aphezulu obulukhuni abonisa izinto eziqinile, kuyilapho amanani aphansi abonisa ukuguquguquka okukhulu. Ukuqina kubhekisela ekhonweni lezinto zokuguquguquka ngaphansi kwengcindezi futhi zibuyele esimweni sazo sokuqala lapho kususwa ukucindezeleka. Ukuqina okuphezulu kusho ukuguquguquka okuthuthukisiwe kanye nokuqina.

Eminyakeni yamuva nje, ukufakwa kwezithasiselo ze-silicone ekwakhiweni kwe-TPU kuye kwathola ukunakwa ukuze kufezwe izinguquko ezifiselekayo. Izithasiselo ze-silicone zidlala indima ebalulekile ekuthuthukiseni izici zokucubungula kanye nekhwalithi yobuso be-TPU ngaphandle kokuthinta kabi izakhiwo zobuningi. Lokhu kwenzeka ngenxa yokuhambisana kwama-molecule e-silicone ne-TPU matrix, esebenza njenge-ejenti yokuthambisa kanye nokugcoba ngaphakathi kwesakhiwo se-TPU. Lokhu kuvumela ukunyakaza okulula kweketanga kanye nokwehla kwamandla aphakathi kwama-molecule, okuholela ku-TPU ethambile futhi eguquguqukayo enamanani ancishisiwe obulukhuni.

Ngaphezu kwalokho, izithasiselo ze-silicone zisebenza njengezinsiza zokucubungula, zinciphisa ukungqubuzana futhi zenze ukuhamba kokuncibilika kube lula. Lokhu kwenza kube lula ukucubungula nokukhipha i-TPU, kuthuthukisa umkhiqizo futhi kunciphisa izindleko zokukhiqiza.

I-GENIOPLAST PELLET 345 Siliconmodifier ithole ukuqashelwa njengesithasiselo se-silicone esiwusizo ezinhlelweni ze-TPU. Lesi sithasiselo se-silicone sandise ububanzi bezicelo ze-thermoplastic polyurethanes. Kunesidingo esikhulu ezimpahleni zabathengi, ezimotweni, kumadivayisi ezokwelapha, kumapayipi amanzi, kumapayipi, kuma-handle grips emishini yezemidlalo, amathuluzi, kanye neminye imikhakha yezingxenye ze-TPU ezibunjiwe ezinomuzwa okhululekile futhi ezigcina ukubukeka kwazo lapho zisetshenziswa isikhathi eside.

Izithasiselo zepulasitiki ze-Si-TPV kanye nezilungisi ze-polymer ze-Silike zinikeza ukusebenza okulinganayo kontanga bazo ngentengo efanelekile. Ukuhlolwa kubonise ukuthi i-Si-TPV njengezindlela ezintsha zokwengeza ze-silicone ziyasebenza, ziphephile, futhi zinobungani nemvelo ezinhlelweni ze-TPU kanye nama-polymer.

Lesi sithako esisekelwe ku-silicone sithuthukisa ukushelela kwendawo isikhathi eside kanye nomuzwa wokuthinta ngenkathi kunciphisa izimpawu zokugeleza kanye nokungaguquguquki kwendawo. Okuphawulekayo ukuthi kunciphisa ubulukhuni ngaphandle kokuphazamisa izakhiwo zemishini; isibonelo, ukwengeza i-20% Si-TPV 3100-65A ku-85A TPU kunciphisa ubulukhuni bube yi-79.2A. Ngaphezu kwalokho, i-Si-TPV ithuthukisa ukuguga, ukuphuzi, kanye nokumelana namabala, futhi inikeza ukuqeda oku-matte, okuthuthukisa kakhulu ukukhanga kobuhle bezingxenye ze-TPU kanye nemikhiqizo eqediwe.

I-Si-TPV icutshungulwa njenge-thermoplastic. Ngokungafani nezengezo ze-silicone ezivamile, isakazeka kahle kakhulu futhi ifana kuyo yonke i-polymer matrix. I-copolymer iboshelwa ngokomzimba kwi-matrix..Awukhathazeki ngokuholela ezinkingeni zokufuduka (ezincane 'eziqhakaza').