Imininingwane

Uchungechunge lwe-SILIKE Si-TPV 2150 luyi-elastomer enamandla e-vulcanizate silicone, ethuthukiswe kusetshenziswa ubuchwepheshe obuthuthukisiwe bokuhambisana. Le nqubo ihlakaza irabha ye-silicone ibe yi-SEBS njengezinhlayiya ezincane, kusukela ku-1 kuya ku-3 microns ngaphansi kwe-microscope. Lezi zinto eziyingqayizivele zihlanganisa amandla, ukuqina, kanye nokumelana nokuguguleka kwama-elastomer e-thermoplastic kanye nezakhiwo ezifiselekayo ze-silicone, njengokuthamba, umuzwa othambile, kanye nokumelana nokukhanya kwe-UV namakhemikhali. Ngaphezu kwalokho, izinto ze-Si-TPV zingaphinde zisetshenziswe futhi zingasetshenziswa kabusha ezinqubweni zokukhiqiza zendabuko.

I-Si-TPV ingasetshenziswa ngqo njengezinto zokusetshenziswa, eziklanyelwe ngqo izinhlelo zokusebenza zokubumba ezithinta kakhulu kuma-elekthronikhi agqokwayo, amakesi okuvikela amadivayisi kagesi, izingxenye zezimoto, ama-TPE aphezulu, kanye nezimboni zezintambo ze-TPE.

Ngaphandle kokusetshenziswa kwayo ngqo, i-Si-TPV ingasebenza futhi njengesilungisi se-polymer kanye nesithasiselo senqubo sama-elastomer e-thermoplastic noma amanye ama-polymer. Ithuthukisa ukunwebeka, ithuthukisa ukucubungula, futhi ithuthukisa izakhiwo zomphezulu. Uma ixutshwe ne-TPE noma i-TPU, i-Si-TPV inikeza ukushelela komphezulu okuhlala isikhathi eside kanye nomuzwa omuhle wokuthinteka, ngenkathi ithuthukisa nokumelana nokuklwebheka nokuklwebheka. Inciphisa ubulukhuni ngaphandle kokuthinta kabi izakhiwo zomshini futhi inikeza ukuguga okungcono, ukuphuzi, kanye nokumelana namabala. Ingakha futhi ukuphela okufiselekayo kwe-matte ebusweni.

Ngokungafani nezithasiselo ze-silicone ezivamile, i-Si-TPV inikezwa ngesimo se-pellet futhi icutshungulwa njenge-thermoplastic. Ihlakazeka kahle futhi ngokulinganayo kuyo yonke i-polymer matrix, lapho i-copolymer iboshelwa ngokomzimba kwi-matrix. Lokhu kususa ukukhathazeka kokufuduka noma izinkinga "zokukhula", okwenza i-Si-TPV ibe yisisombululo esisebenzayo nesisha sokufeza izindawo ezithambile ezithambile kuma-elastomer e-thermoplastic noma amanye ama-polymer. futhi ayidingi izinyathelo ezengeziwe zokucubungula noma zokufaka.

Izinzuzo Eziyinhloko

- Ku-TPE

- 1. Ukumelana nokuguguleka

- 2. Ukumelana namabala nge-engeli encane yokuxhumana namanzi

- 3. Yehlisa ubulukhuni

- 4. Cishe akukho thonya ezimpahleni zemishini ngochungechunge lwethu lwe-Si-TPV 2150

- 5. Ama-haptic amahle kakhulu, ukuthinta okomile okusilika, akukho ukuqhakaza ngemuva kokusetshenziswa isikhathi eside

Ukuqina Ukuqina

- Ubuchwepheshe obuthuthukisiwe obungenazo izinyibilikisi, ngaphandle kwe-plasticizer, akukho uwoyela wokuthambisa, futhi awunaphunga.

- Ukuvikelwa kwemvelo kanye nokusetshenziswa kabusha kwayo.

- Itholakala ngezinhlobo ezihambisana nomthetho.

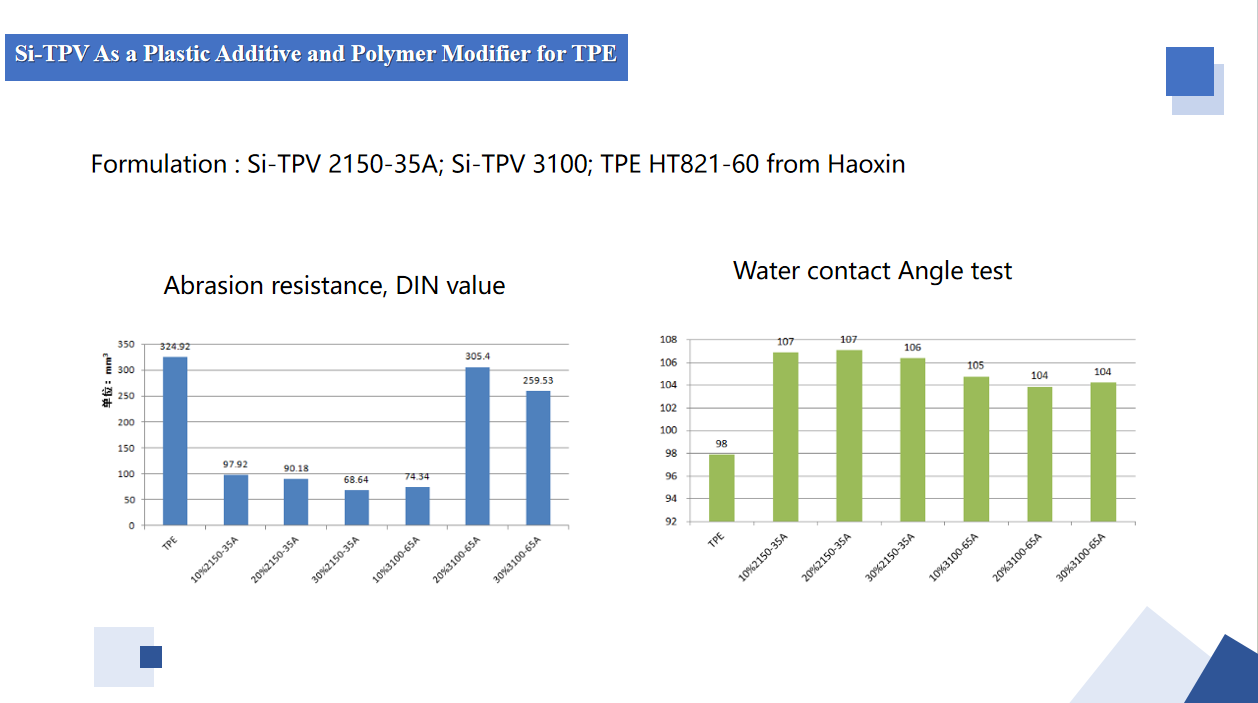

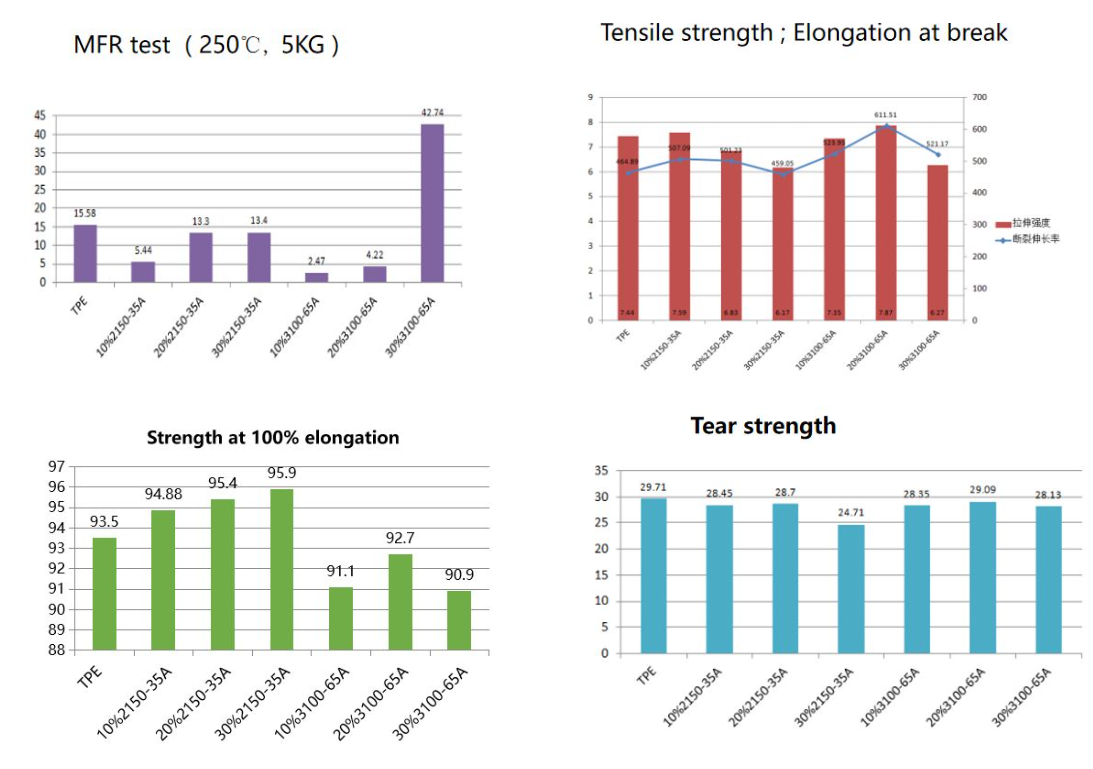

Izifundo Zezimo Zesithasiselo sepulasitiki se-Si-TPV kanye nesiguquli se-polymer

Uchungechunge lwe-Si-TPV 2150 lunezici zokuthintwa okuthambile okuhlala isikhathi eside okunobungani nesikhumba, ukumelana okuhle kwamabala, akukho pulasitiki kanye nesithambisi esengeziwe, futhi akukho mvula ngemva kokusetshenziswa isikhathi eside, okusebenza njengesithasiselo sepulasitiki kanye nesiguquli se-polymer, ikakhulukazi esisetshenziselwa ukulungiselela ama-elastomer e-thermoplastic athambile futhi athambile.

Ukuqhathanisa Imiphumela ye-Si-TPV Plastic Additive kanye ne-Polymer Modifier ekusebenzeni kwe-TPE

Isicelo

I-Si-TPV isebenza njengesilungisi sokuzizwa esisha kanye nesithasiselo sokucubungula ama-elastomer e-thermoplastic namanye ama-polymer. Ingahlanganiswa nama-elastomer ahlukahlukene kanye nobunjiniyela noma amapulasitiki ajwayelekile, njenge-TPE, TPU, SEBS, PP, PE, COPE, EVA, ABS, kanye ne-PVC. Lezi zixazululo zisiza ukuthuthukisa ukusebenza kahle kokucubungula futhi zithuthukise ukusebenza kokumelana nokuklwebheka nokuklwebheka kwezingxenye eziqediwe.

Inzuzo ebalulekile yemikhiqizo eyenziwe nge-TPE kanye ne-Si-TPV blends ukudalwa komuzwa othambile nothambile ebusweni—okuyiwona kanye umuzwa othintekayo abasebenzisi abawulindele ezintweni abazithinta noma abazigqokayo njalo. Lesi sici esiyingqayizivele sandisa ububanzi bezinhlelo zokusebenza ezingaba khona zezinto ze-TPE elastomer kuzo zonke izimboni. Ngaphezu kwalokho, ukufaka i-Si-TPV njengesiguquli kuthuthukisa ukuguquguquka, ukuqina, kanye nokuqina kwezinto ze-elastomer, ngenkathi kwenza inqubo yokukhiqiza ibe ngcono kakhulu.

Izixazululo:

Ingabe Ulwela Ukuthuthukisa Ukusebenza Kwe-TPE? Izithasiselo Zepulasitiki ze-Si-TPV kanye nezilungisi ze-polymer zinikeza impendulo

Isingeniso kuma-TPE

Ama-elastomer e-Thermoplastic (ama-TPE) ahlukaniswa ngokwezakhi zamakhemikhali, okuhlanganisa ama-Thermoplastic Olefins (TPE-O), ama-Styrenic Compounds (TPE-S), ama-Thermoplastic Vulcanizates (TPE-V), ama-Polyurethanes (TPE-U), ama-Copolyesters (COPE), kanye nama-Copolyamides (COPA). Ngenkathi ama-polyurethanes nama-copolyesters engase aklanywe ngokweqile kwezinye izindlela zokusetshenziswa, izinketho ezingabizi kakhulu njenge-TPE-S kanye ne-TPE-V zivame ukunikeza ukulingana okungcono kwezinhlelo zokusebenza.

Ama-TPE avamile ayinhlanganisela ebonakalayo yerabha kanye ne-thermoplastics, kodwa ama-TPE-V ahlukile ngokuba nezinhlayiya zerabha ezixhumene kancane noma ngokugcwele, okuthuthukisa ukusebenza kwazo. Ama-TPE-Vs afaka amasethi okucindezela aphansi, ukumelana okungcono kwamakhemikhali nokuklwebheka, kanye nokuqina okuphezulu kokushisa, okwenza afaneleke kakhulu ekushintsheni irabha ezivalweni. Ngokuphambene nalokho, ama-TPE avamile anikeza ukuguquguquka okukhulu kokwakheka, amandla aphezulu okuthambekela, ukunwebeka, kanye nombala, okwenza afaneleke emikhiqizweni efana nezimpahla zabathengi, izinto zikagesi, kanye namadivayisi ezokwelapha. Aphinde ahlangane kahle nezinto eziqinile ezifana ne-PC, i-ABS, i-HIPS, kanye ne-Nylon, okuzuzisayo ekusetshenzisweni okuthambile.

Izinselele ngama-TPE

Ama-TPE ahlanganisa ukuqina kwamandla okusebenza kanye nokucutshungulwa kalula, okwenza abe nokuguquguquka okukhulu. Izakhiwo zawo zokuqina, njengesethi yokucindezela kanye nokwelulwa, zivela esigabeni se-elastomer, kuyilapho amandla okuqina nokuklebhuka encike engxenyeni yepulasitiki.

Ama-TPE angacutshungulwa njenge-thermoplastics evamile emazingeni okushisa aphezulu, lapho angena khona esigabeni sokuncibilika, okuvumela ukukhiqizwa okuphumelelayo kusetshenziswa imishini yokucubungula ipulasitiki ejwayelekile. Ububanzi bawo bokushisa bokusebenza buphawuleka futhi, kusukela emazingeni okushisa aphansi kakhulu—eduze nephuzu lokushintsha kwengilazi lesigaba se-elastomer—kuya emazingeni okushisa aphezulu asondela endaweni yokuncibilika yesigaba se-thermoplastic—okwengeza ekuguquguquka kwawo.

Kodwa-ke, naphezu kwalezi zinzuzo, kunezinselele eziningana eziqhubekayo ekwenzeni ngcono ukusebenza kwama-TPE. Inkinga enkulu ubunzima bokulinganisela ukuqina kwamandla omshini. Ukuthuthukisa isici esisodwa kuvame ukubiza esinye, okwenza kube nzima ngabakhiqizi ukuthuthukisa amafomula e-TPE agcina ibhalansi ehambisanayo yezici ezifunwayo. Ngaphezu kwalokho, ama-TPE asengozini yokulimala kwendawo njengokuklwebheka nokubola, okungathinta kabi ukubukeka nokusebenza kwemikhiqizo eyenziwe ngalezi zinto.